欧博abgEsco Group

Different type of products

... for various industriesprev

next

Agriculture

Machine and plant building, compact machines, pumps and fans, conveyors, compressors, elevators, lifting and crane applications, building automation HVAC, packaging machines, industrial applications, textile machines, heating, ventilation and air-condition.

Cement

The cement industry needs rugged and reliable drive systems as chocks and aggressive environmental influences are quite demanding for production installations. Power transmission products should be selected taking this into account and therefore, well-sealed products are preferred to avoid contamination by dust penetration. Escogear and Escodisc couplings have optimized design features such as flange connections and a sealing system to comply with this requirement.

Food industry, oil mills and meat processing

Today, meeting the increased demand for natural oils depends on the reliability and production capacity of oil mills, which are at the heart of the current bio-based nutrition pattern. Escogear couplings contribute to the reliable production performance of these installations, with their high-quality gearing permitting a high output and sustainable production with the minimum downtime.

General machines

Engineered Escogear and Escodisc coupling products are used, among other things, to drive motor test stands, turbine simulators, brake test stands and balancing machines, to name but a few. Test benches are so specific that special custom designed couplings are often required to fulfill the needs of the application. The flexibility of ESCO Couplings engineering staff to understand customers’ requirements and to react quickly with short communication tracks means that our unique solutions are appreciated by the customer.

Petrochemicals & Refinery

Petrochemicals and refineries are a major field of application for Escodisc couplings as their use drastically reduces customers’ operational costs. For reliable production, it is essential that production processes run smoothly and for an extended period of time. Escodisc couplings are completely machined with an inherently high degree of balance and are ideally suited to drive rotating equipment such as pumps and compressors smoothly as Escodisc couplings’ main unique features are maintenance free and designed for "infinite life".

Power Generation

Electricity is at the heart of every household and factory and must therefore have maximum availability. All power plants use the same principle for operation; they convert energy into electricity. The energy can be of thermal, solar, wind or water origin. Escogear and Escodisc couplings connect the driving machines to the electric generators to smoothly transfer the mechanical energy created to the electricity generators.

Quarrying & Mining

Escogear couplings are built to support and be resistant to the heavy-work and extreme conditions of the mining industry. The major conveyor in the Coal Mine has been driven for years by an Escogear FST size 530, with a gearbox shaft with a diameter of 500 mm.

Application: Conveyor

Couplings used: Gear coupling

Customer: Tata Steel Mines in Odisha/Jharkhand

Rail

Today, public transportation increasingly relies on metro and tram systems, the most efficient way of commuting in large cities. These days distances between cities of up to 1000 km are easily covered faster, more efficiently and comfortably by high-speed trains than by planes. Downtown commuting by metro or street car has become the normal mode of transport in larger cities.

Esco Couplings therefore developed Escogear FTRN couplings, a complete range of traction couplings dedicated to the rail industry.

Renewable energy

Windmills applications need small, light couplings with high misalignment capacities and high-power densities, in combination with brake discs and overload devices.

Esco couplings has succeeded in designing such specific couplings. And what is more, the high axial capacity of Escogear couplings makes the construction of the driveline much simpler and in addition, assembly is faster and easier.

Steel & non-ferrous

From the Eifel tower to oil platforms, paper clips, artificial hips, cars, couplings and much more. It can be said that steel and non-ferrous materials are literally used as a basic material everywhere.

Textile

Textiles are not only used for clothing. Industrial uses as well as automotive applications these days demand reliable and highly productive machinery. These are typically 365/7/24 applications which apart from being robust must also be competitive. Escogear and Escodisc couplings fulfil requirements as a function of each application within the space envelope and the specification submitted, whether for torque and/or alignment and/or function.

Wood, Pulp & Paper

Whether for printing or writing by hand, paper is still an important part of quality communication and must therefore be of the highest quality, requiring that the fibers used are of the finest quality.

Multicrown gearing for high-misalignment rail traction

Torque up to 30,000 Nm+

Bore up to 120 mm+

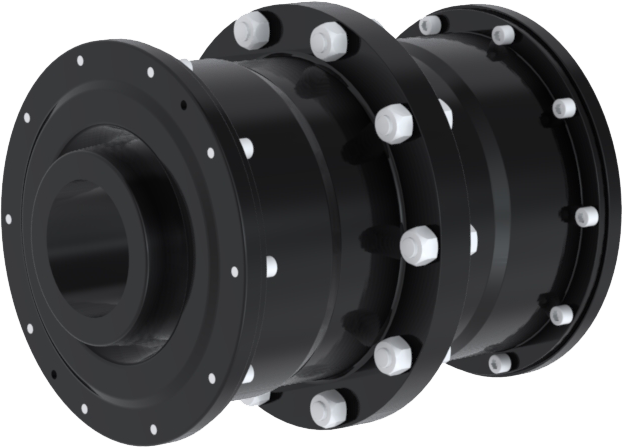

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc pack version with extremely short DBSE

Torque up to 29,600 Nm

Bore up to 350 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Multidisc and flange packed subassembly version with anti-spark and anti-fly (optional)

Torque up to 23,100 Nm

Bore up to 220 mm

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Multidisc and flange packed subassembly version with anti-spark and anti-fly (optional)

Torque up to 23,100 Nm

Bore up to 220 mm

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Multidisc and flange packed subassembly version with anti-spark and anti-fly (optional)

Torque up to 23,100 Nm

Bore up to 220 mm

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc and flange packed subassembly version with anti-spark and anti-fly (optional)

Torque up to 23,100 Nm

Bore up to 220 mm

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc pack version with extremely short DBSE

Torque up to 29,600 Nm

Bore up to 350 mm

Multidisc and flange packed subassembly version with anti-spark and anti-fly (optional)

Torque up to 23,100 Nm

Bore up to 220 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc pack version with extremely short DBSE

Torque up to 29,600 Nm

Bore up to 350 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc pack version with extremely short DBSE

Torque up to 29,600 Nm

Bore up to 350 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc pack version with extremely short DBSE

Torque up to 29,600 Nm

Bore up to 350 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc pack version with extremely short DBSE

Torque up to 29,600 Nm

Bore up to 350 mm

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

Multidisc pack version

Torque up to 260,000 Nm

Bore up to 370 mm

Multidisc pack version with extremely short DBSE

Torque up to 29,600 Nm

Bore up to 350 mm